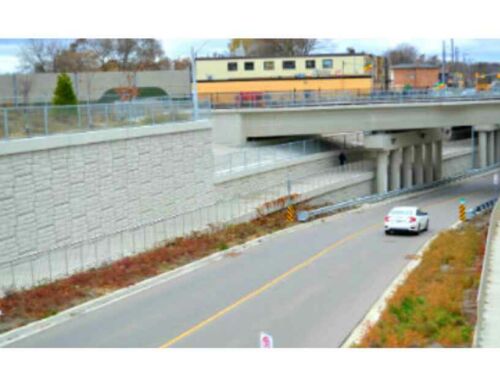

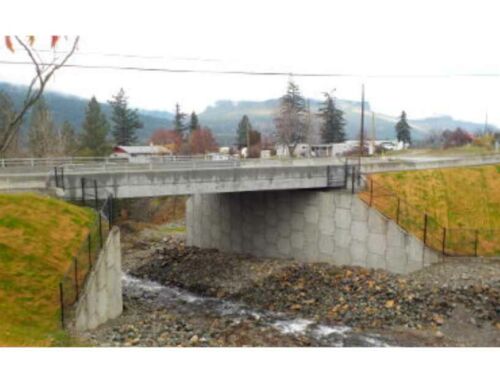

With ever increasing population and demand for an improved infrastructure and transportation systems, the City of Markham’s expansion plans included the extension and reconstruction of Rodick Road. As a part of the extension, the Reinforced Earth® wall system was selected for the approach ramps and abutments of the CN overpass.The geometry of the overpass dictated a 52˚ skew at the abutments which led to a 38˚ acute corner in the MSE wall.

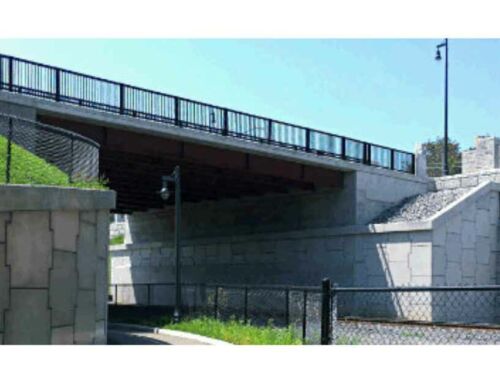

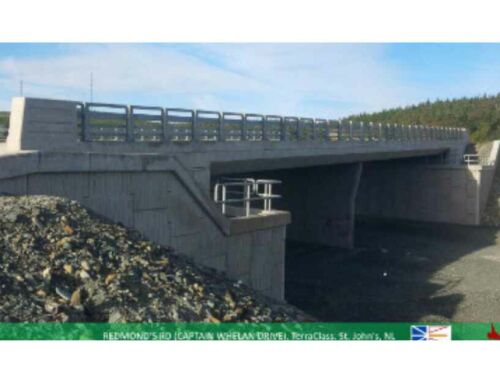

The Rodick Road extension project (phase 3) is located between 14th Avenue and Esna Drive in Markham, Ontario in order to facilitate the traffic over the CN rail. This project is owned by the City of Markham, who awarded the design package to UMA/Aecom. Dagmar Construction secured the construction work that started in September 2011. The total of 4000 m2 of Reinforced Earth® walls is distributed between abutments and the retaining walls at the north and south sides of the bridge. The maximum height of the walls is approximately 13 m.

The bridge abutment carries the traffic load on two false abutments supported by 8 concrete columns, 1200 mm diameter, at each side over spread footings encased with precast concrete (TerraClass®) facing walls. A wire mesh facing wall system (TerraTrel®) was also used to retain the backfill behind the CIP abutments.

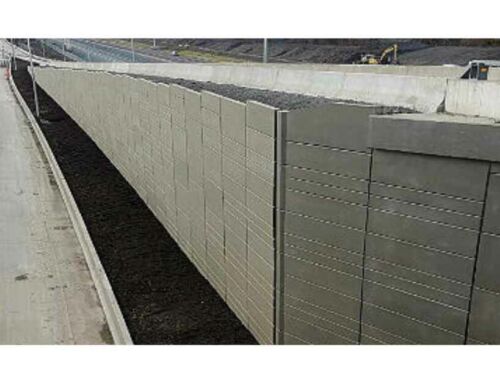

Based on the Reinforced Earth wall theory and in order to take advantage of full capacity of the soil reinforcing strips, these reinforcements should be installed perpendicular to the wall facing. Since the bridge columns obstructed the strips behind the panels, in many locations the reinforcing strips had to be skewed to avoid the columns. The strip reinforcement in Reinforced Earth wall system can revolve around the bolted connection behind the panel. This is one if the advantages of the strip soil reinforcement against any grid soil reinforcements. Accordingly the MSE walls were designed to account for the strength reduction due to skew angle of the strips and in some occasions, auxiliary components were utilized to secure the strips to the facing panels. The main component used for this purpose was a double galvanized structural steel angle placed back to back with multiple holes which provided extra connecting points to the panels.

Due to the geometry of the new road, the overpass bridge has a skew angle of approximately 52°, which resulted in producing an acute internal angle of 38° between the back faces of the wall panels and the abutments. This geometry prevents the reinforcing strips from being placed perpendicular to the panels as they should be; furthermore it does not allow the strips to be skewed efficiently to avoid conflict with the opposite wall. In order to make the panels at these locations stable, a uniquely designed solution to this problem was applied. Special smooth galvanized strips were utilized to connect the opposing panels together at specific locations where it was difficult to install a full length strip. This was the tightest skew angle ever constructed in Canada by Reinforced Earth Company and also the first time we utilised the smooth reinforcement in this fashion of “cross-ties” to form a bin style wall.