A French engineer’s invention in 1963 developed a new composite material using earth as a raw material, which spawned the development of a company with offices across five continents in just a few decades. Easy-to-use Reinforced Earth® mechanically stabilized earth retaining wall technology quickly took hold as an ideal reinforced backfill solution in an array of applications in many market sectors. The technology’s inventor and Reinforced Earth® founder, Henri Vidal, transformed his revolutionary idea to become an entrepreneurial breakthrough.

Reinforced Earth Company Ltd. (RECo), the Canadian company established in April 1970, was the first commercially registered Reinforced Earth company in the world and is a subsidiary of the Terre Armee and Soletanche Freyssinet Group. We are a leader in the design and supply of proprietary mechanically stabilized earth retaining wall systems. Our experience is proven in major highway, mining, and infrastructure projects.

RECo first started its activities in Quebec, where projects were successfully and repeatedly proven for the Ministry of Transportation Quebec (MTQ) on various highways across the province such as Highways 132, 440, 185, 15, 440, and 138. Other applications included projects for the St. Joseph Oratory in Montreal, for Hydro Quebec at Manic Dam and James Bay.

RECo’s westward service commenced in 1978, obtaining formal approvals from various Ministries of Transportation in Ontario, Manitoba, Saskatchewan, Alberta, and British Columbia. Significant mechanically stabilized earth retaining wall structures were built in the early 1980’s on projects such as the Burlington Skyway, Kananaskis Highway, Trans-Canada Highway at Banff, Norquay, Vermillion, and Jasper, as well as on Vancouver Island at Duncan. Other unique Reinforced Earth® projects were built in industrial applications for a 45,000-tonne Obed Marsh coal storage facility for Union Oil up to 30 meters in height using sloped-panel technology, and large urban applications for the Ottawa Transit Way and LRT in Calgary during the same period.

RECo continued to receive confidence from various transportation authorities in the mid 1980’s where 59 projects were built in British Columbia, Alberta, Ontario, and Quebec between 1994 and 1996. Over 235,000 square meters of numerous Reinforced Earth® structures including bridge abutments were used on major highways such as the 115 km Coquihalla Highway, the 25 km Sea to Sky Highway 99 reconstruction in B.C. and the 30 km of coastal Route 132 in the Gaspé Peninsula in Quebec. RECo’s industrial technologies were also introduced to large load supported truck dump projects in 1984 for Syncrude Canada Ltd. at Fort McMurray, while Edmonton Power selected RECo and successfully completed a 45,000-tonne coal storage project at Genesee.

RECo during the last five decades served our coast to coast Canadian customers with a diversified portfolio and more innovative technologies with TerraTrel, TechSpan precast arches, and Underwater Walls. RECo’s consistent ability and competitiveness are also evident by our participation across Canada in well known major projects, from the Vancouver Island Highway in B.C., the Syncrude, and Suncor works at the North Mine, Steepbank, and Millennium sites in Alberta, to the Highway 407 and LBPIA projects in Toronto, Ontario and the Highway 104 works in Nova Scotia, Atlantic Canada.

Since 1970, Reinforced Earth Company Ltd. (Canada) has served numerous satisfied and repeat clients and has completed thousands of successful projects with a face area of over 1.7 million square meters of RECo structures from Vancouver Island to Newfoundland. In 2005 RECo Canada expanded its geographical territory to include the islands of the Caribbean too.

OUR HISTORY

-

Patent filed for Reinforced Earth®: French engineer Henri Vidal files the patent for Reinforced Earth® and becomes the modern inventor of what is now commonly referred to as Mechanically Stabilized Earth (MSE). Much like this combination of pine needles and sand, metal or geosynthetic reinforcing strips placed at regular intervals […]

-

First structure built in Percè, Quebec, Canada: Our history started in 1970 when the first Reinforced Earth structure on Canadian soil was built in Percé, Quebec. After this, the French invention explosively expanded to the rest of Canada and the world.

-

St. Joseph Oratory: On the site of Canada’s largest church, this retaining wall features a raised architectural finish, designed for a 200+ year service life as required by the Church.

-

Tremplin de ski Mont Ste-Anne: The elevation difference is 24m in 52m (slope 47%). Possibly the only application of its kind to date, this ski jump highlights the ability for RE to be constructed on very steep mountainous terrain.

-

Gaspe Seawalls: Since its construction, the approx. 30-km long RE walls have buffered Route 132 from tidal fluctuations with up to 6 m swells, extensive ice flows and ice formations, and other severe cold weather conditions inherent to the region.

-

Kananaskis Country: The use of RE walls allowed for an efficient “cut and fill” to minimize the need for importing of fill material.

-

Yellowhead Trail: This “tight diamond” intersection shows that RE can prove cost effective in not only the traditional “fill” applications but also in this 8 meter “cut”.

-

Vancouver ALRT: The first application of RE for Light Rail Transit (LRT) in Canada, similar applications are now extremely common today, almost 40 years later. The City of Vancouver’s SkyTrain is one of the longest LRT systems in Canada.

-

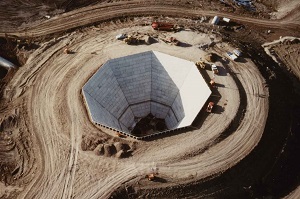

Obed Slot: This coal storage structure features a 28m-high conical storage that with the completed roof structure provide protection of coal from the elements and allows ‘first in, first out’ coal storage with no dead storage spots.

-

Coquihalla Highway: RE technology is a suitable method of reducing rock drilling and blasting. For high walls constructed in mountainous areas, the cost savings of RE compared to other retaining wall types is dramatic.

-

Harvey Creek Bridge: This split-level true abutment application is quite unique and provides protection of the highway from the devastating loss of bridges in the past caused by the creeks’ avalanches of debris flows.

-

Cominco Bridge: This RE ‘true abutment’ was designed to carry a single mine vehicle of 244t over a two-lane highway.

-

R.H. Saunders UWW: One of the four walls of its type in Canada utilizing a special panel and construction technique which allows construction underwater in depths up to 6 meters.

-

Terminal 3: The tight location of roadways and ramps at airports can utilize the benefit of RE technology.

-

Miramichi UWW: This 6m high R/E wall constructed underwater supports a maritime museum in the province of New Brunswick.

-

Lime Kiln Bay Wharf: These ramp walls for the Atlantic Salmon Growers are constructed in the Bay of Fundy and were required to be designed for a 7m high tidal fluctuations.

-

Vancouver Airport: Airport developers gravitate to RE for the superior aesthetics.

-

Rocky Creek: This 18m span TechSpan precast arch was the winning alternative to span Rocky Creek on Vancouver Island and maintain this environmentally sensitive creek.

-

Ocean Pond: By eliminating the need for expansion joints or bearing pads required for a short span bridges, this TechSpan arch in Newfoundland requires very low maintenance.

-

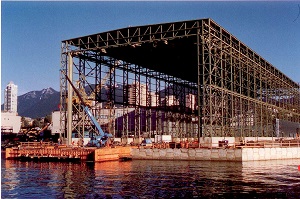

BC Ferry Assembly Building: The RECo team worked efficiently from the conceptual design to supply stage on this fast-tracked project, ultimately re-designing and supplying to site in 3.5 weeks.

-

Bishops Falls: This application of Techspan in Newfoundland has been followed by nearly one dozen.

-

Holdich Creek/ Hwy 23 Walls: After a washout of the only highway access to a remote community in BC and under emergency repair contract, this TechSpan arch application features the tallest TechSpan headwalls in the world at a height of 23m.

-

Muskeg Froth Tank Walls: This project was the first time in the world that RE walls were used to support a settling tank. The six structures constructed for an oil sand client also featured a tunnel composed of RE wall and short span roof bridge.

-

Georgia-Pacific Melford Mine: Constructed under a Joint Venture with a local contractor this project featured several of RECo’s techniques including, truck dump wall, reclaim tunnel under Gypsum stock pile and an emergency escape tunnel composed of RE and overhead short-span roof slabs.

-

Georgia-Pacific Surge Tunnel: The use of TechSpan precast arch with 3 access holes in the roof under a Gypsum surge pile allowed for the reclaiming of Gypsum into the tunnel and onto a conveyor.

-

Margaree Harbour Bridge: Built in one of the many scenic areas of Nova Scotia, this project utilized the ability of RE walls to be constructed with aesthetically pleasing curves.

-

Children’s Hospital Interchange: One of the most interesting uses of the aesthetic combination of a raised finish and painted concrete in the Calgary area.

-

Snider Grade Separation: This rail-over-rail interchange represents the largest project in Canada where heavy rail is supported directly and in close proximity to the face of the wall.

-

Esther Shiner Blvd: In addition to the aesthetics of our ashlar stone finish, this project features the use of recycled concrete as backfill that was taken from a huge concrete floor slab of an old Canadian Tire store just a hundred meters or so from the wall construction.

-

Cranston Development: One of the most interesting uses of the aesthetic combination of a raised finish and painted concrete in the Calgary area.

-

Walsh River: Supporting heavy rail access to and iron ore mine these head walls over precast arches were constructed under a compressed project schedule during early winter in north Labrador.

-

Port Cartier Seawall: Constructed at low tide in Quebec’s tidal zone of the Gulf of Saint Lawrence this was the first RE wall to utilize our GeoStrap Polyester soil reinforcement used to avoid concerns of the salt water corrosion would have on metallic reinforcement.

-

Rodick/CNR: When acute corners are required from RE design, special attention to design and construction is necessary.

-

Mt. Milligan Copper-Gold Project: A Reinforced Earth wing wall for the primary crusher structure and truck dump for this mine is the highest wall of its kind in Canada with 33m of vertical facing.

-

Stock Yards Village Shopping Centre: As part of a Commercial development in the City of Toronto, RECo teamed up with our sister company Menard who provided two different types of foundation improvements on the poor soils under the RE walls.

-

Bonaventure Montreal: Using a unique architectural finish with TerraPlus concrete panels, construction of this important access way in Montreal was achieved with minimal impact to downtown traffic.

-

Mahogany Land Development: The ability to accommodate unique geometries made RE walls the preferred choice for this manmade lake in a new upscale housing development in Calgary.

-

2nd Concession Rd Bridge over GO Rail: Bridges spanning an active rail corridor and the Holland River lift the reconstructed 2nd Concession out of the valley. The environmental footprint of the roadway is further minimized through curvilinear and terraced tree-patterned retaining walls. At road level, cyclists travel on dedicated cycle […]

-

James Potter Road Underpass: The consultant along with the city specified aesthetic features for the precast concrete panels, proposing a two “Ribbons in the wind” concept. With 80 different patterns, RECo achieved the aesthetic look that owners envisioned.

-

Echangeur Turcot: This project was the largest RE project in Canadian History with approximately 100,000m2 of wall area of TerraPlus panels.

-

Regina By-Pass Ring Road: Regina Bypass is the largest transportation infrastructure project in Saskatchewan’s history. RECo’s contribution to the project consisted of 44 structures, a total wall area of 23,000m2.

-

Southwest Transitway: The City of Winnipeg’s Southwest Rapid Transit Corridor project in Manitoba is a dedicated high-speed roadway for buses, integrating all existing bus routes in Southwest Winnipeg and bypassing several areas of traffic congestion on the major Pembina Highway. The project, owned by the City of Winnipeg, is anticipated […]

-

162nd Street & Macleod Trail Interchange: An interesting architectural treatment jointly developed between RECo and owners’ architects resulting is a visually striking final result.

-

Hydro-Quebec Barrage De La Trenche: A 17m long TechSpan project with 45m long headwalls using TerraPlus panels in smooth grey finish.

-

Ojibway Parkway Overpass: A Retained soil system with high performance high appearance that has an architectural finish built in Windsor Ontario.

-

50th Anniversary: Over the last 50 years, RECo Canada has forged an unrivalled level of expertise and experience in reinforced backfill applications and soil-structure interaction. Our experience is proven with our participation in a wide variety of Canadian markets and applications using our iconic retaining wall systems and innovative product […]

-

Aurum Road : TerraClass RE panels were used to build headwalls and wing walls for the Aurum Road culvert in the city of Edmonton with a service life of 100 years. The Consulting Engineers of Alberta recognized the project with the Award of Excellence in recognition of its positive environmental […]

-

Little Barasway River Bridge: A 10m wide TechSpan with a 129 sqm head wall of RE walls were used to build this short span bridge.

-

Reversing Falls Railway Bridge Rehabilitation: Due to the advanced degradation of the concrete in the piers of Reversing Falls Railway Bridge, a 20m high Mechanically Stabilized Earth (MSE) wall was constructed to replace the existing bridge between the West abutment and Pier 4. This involved taking the degraded piers out […]

-

Kicking Horse: The Kicking Horse Canyon Phase 4 Project, in British Columbia involves realigning and widening 4.8 km of highway through the canyon. This last phase is the most technically challenging and difficult part of whole 4 phased project considering the location, along with little disruption as possible to highway […]