Reinforced Earth Company was retained to design and supply the retaining wall for the Mount Milligan project in British Columbia for a primary crusher structure and truck dump. It is in fact the highest MSE wall in Canada with 33m of vertical facing. The Mount Milligan mine is located 155 km northwest of Prince George, and mid-way between communities of Fort St. James and Mackenzie in central British Columbia.

This mine is an open pit copper-gold mine which will produce 60,000 tonnes per day over its 22-year mine life. According to the Mount Milligan website, the reserve is estimated at 2,124 million lb of copper and 6.02 million oz of gold. As a part of the process, the extracted ore needs to be fed into the primary crusher for crushing and screening. In order to offload the ore, the haul trucks require a ramp to the top of dump pocket that includes two Reinforced Earth walls at each side of the primary crusher structure.

Thompson Creek Metals is the owner of the project. British Columbia Mining Joint Venture by Fluor and Amec carried out the project design for this dump wall. Geotechnical study was conducted by Knight Piesold Consulting which checked the external and global stability of the structure. The construction was carried out by Duz Cho Construction as the prime contractor and Formula Contractors as subcontractor for the Reinforced Earth walls.

The mining equipment for operating at this location is CAT 793F Trucks and a MANITOWOC 2250 Crane.

The crane load is 300 ton that exerts a distributed pressure of approximately 40 kPa under its tracks. A reinforced concrete slab is constructed on top of the Reinforced Earth wall to distribute this load and the wheel load of the 300 ton dump trucks. The equivalent surcharge used in the design of the retaining wall is calculated 50 kPa.

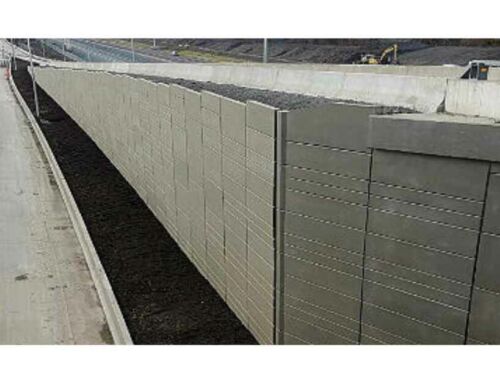

The retaining walls are designed for a service life of 23 years and due to this short design life, TerraTrel® facing (wire mesh) was selected. In order to increase the durability of the facing and also protect the wall from possible crash of machinery at the toe of the wall, a zone of rockfill was considered behind the TerraTrel® facing. The total area of the wall is about 5000m2 with the length of 180m. More than 13,600 pieces of reinforcing strips are used in the Reinforced Earth wall. In the highest MSE wall in Canada more than 225km of reinforcing strips is used! The construction of the wall started in July 2012 and was completed in November 2012. The construction rate is reported 50m2 a day approximately. To complete this huge project, more than 90,000m3 granular material was placed and compacted.

The Mount Milligan Primary Crusher dump wall demonstrates that with the proper selection of backfill materials and with good detailing of the wall components, Reinforced Earth walls can be successfully designed and constructed to significant heights with vertical facing to support high surcharge and pressure. Also it shows the TerraTrel® facing in mining applications with medium service life structures is an excellent solution. The Mount Milligan Project encourages us to design even higher structures.