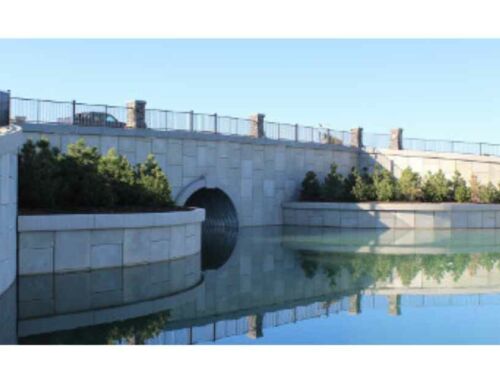

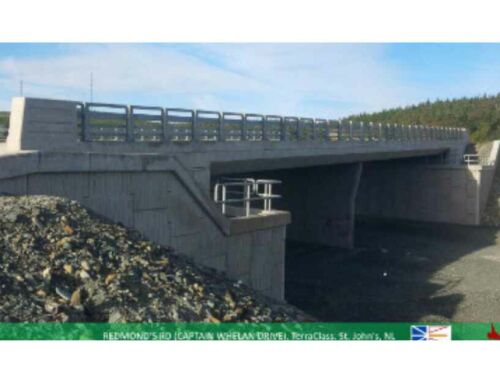

The Newfoundland and Labrador Ministry of Transportation and Works requested a TechSpan concrete arch culvert constructed over the Waterford River to support a 19 m high embankment for the Team Gushue Highway Extension.

Named in honour of the 2006 Olympic Gold medalist curling team, the Team Gushue highway once completed will provide a vital link to the NW Avalon Peninsula. The highway is designed to relieve traffic congestion on all major routes in the region, and when finished, will connect the Outer Ring Road in the north with Robert E. Howlett Memorial Drive to the south.

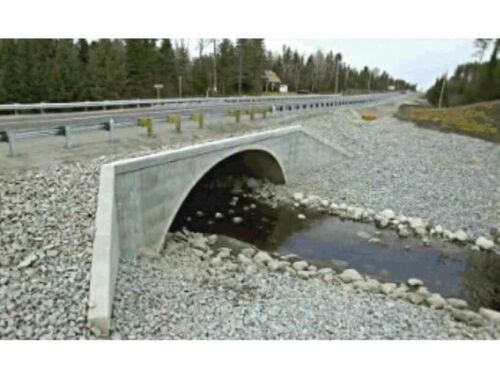

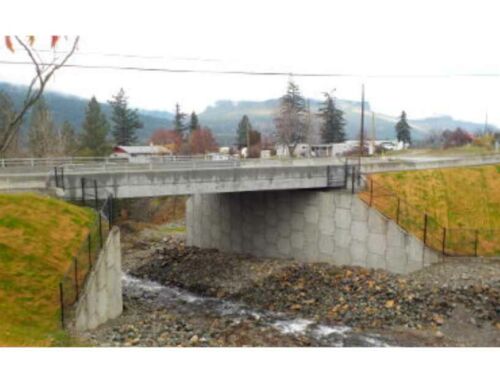

The Waterford river crossing was a major technical and construction challenge on this project. The 10 m wide river runs in a 19 m deep meandering gorge and has a swift current, making work in and around the river challenging. Access to the site was extremely difficult. Two very steep grade construction roads on each side of the river connected by a temporary bridge provided access to the bottom of the gorge and the erection site. A temporary diversion of the river permitted for excavation and site casting of two 5.35 m wide footings and the erection of the concrete arch culvert in the dry. The 63m long, 11m span, 4m high concrete arch structure supports 19 m of overburden and the highway road base, allowing the highway a level crossing of the gorge and river.

The Waterford river crossing structure was not considered in great detail until just before the project was under review for Environmental Approval. The initial hydrology study indicated an arch pipe would suffice hydraulically and be comparable to upstream structures on the river. The initial structure was conceived to be longer but in order to lessen the footprint of the structure to have a lesser impact on the river, the structure was shortened and headwalls were increased to retain more fill. Further changes were made during construction to make the constructability smoother so the location of the structure and wall configuration was again revised resulting in the final configuration.

The precast arch extension is an 11 m span with an internal rise of 4 m and a thickness of 0.25 m. The earth cover over the crown to highway is approximately 16.5 m with the side slope on the embankment. The principle concept depends on the development of a finite element program based on funicular curve theory for which the bending moment at any point is zero. The arch is a 3 hinged arch shape that minimizes tensile stress in the concrete. The design of the arch considers all loads anticipated on the arch elements during transportation, erection, and backfilling and in-service.

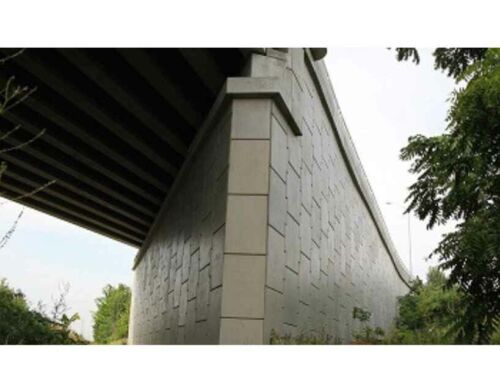

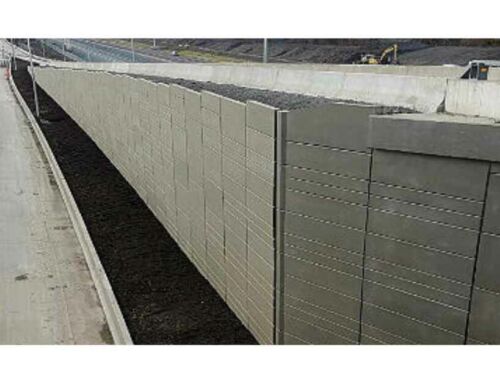

The pre-cast concrete arch shape was calculated by a finite element method and formed in special flexible moulds to fit the existing shape of the structure and MSE walls were used as the wing walls and head walls while the structures were designed to sustain the high overburden. The innovation of pre-cast concrete arch is to utilize a pre-cast product with a sophisticated and individual design approach incorporating the optimum arch geometry and individually suited to the various loading situation for unique structures like this.

The pre-cast arch used on this project is the TechSpan® product by Reinforced Earth Company Ltd. and is built by assembling prefabricated concrete elements in a staggered and symmetrical way to allow a fast installation without disrupting the traffic below.

The governing phenomenon in the behaviour of an earth-filled precast arch is the relative stiffness of the concrete structure compared with the soil behind it. For a precise analysis of the behaviour of the concrete arch, in relation to the fill during backfilling and in its service stage, a finite element analysis is required. The state-of-the art design program developed by RECo uses a finite-element-method to optimize the arch shape and minimize the bending moments in the concrete. The use of a FEM program is commonly considered to be the most effective way to analyze the soil and structure interaction of buried arches.

The analysis includes all of the various load cases which include stripping & handling during fabrication, transportation, installation, backfilling and rail surcharge on final fill condition. Based on the most critical load cases for all combinations, the arch was optimized for both thickness and rebar design for the required design codes and specifications.